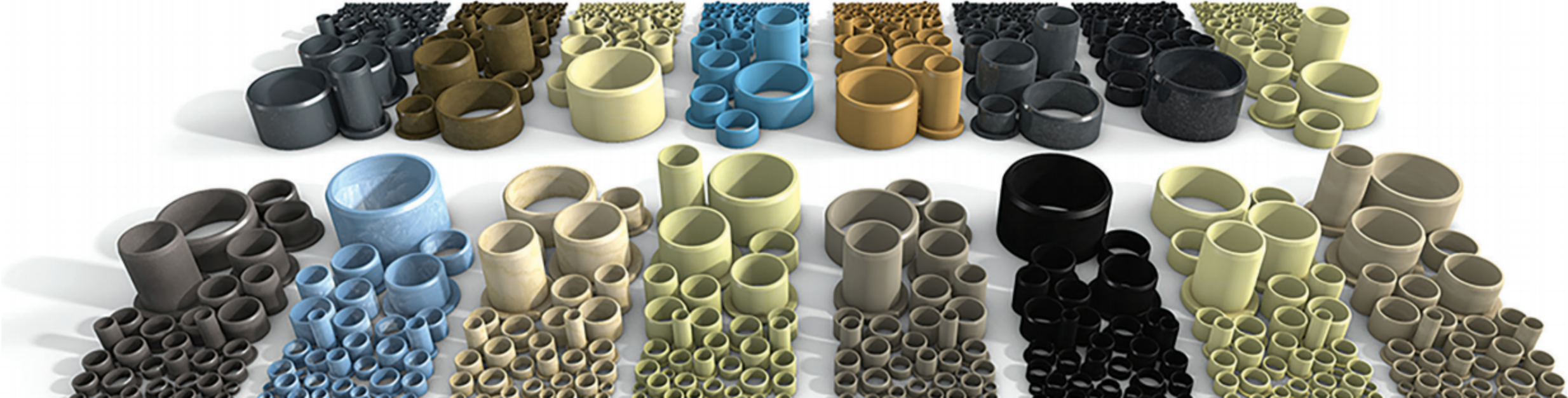

Composite plastic bushings combine thermoplastics, fibers and filaments, and solid lubricants for tailored bearing solutions with predictable life in a wide variety of applications.

These bushings operate without maintenance or external lubrication, resist corrosion and debris, fit precisely, and dampen vibrations while maintaining high compressive strength at a lower cost than comparable metal products.

Read on for the top 10 reasons to consider composite plastic bearings.

1. Lighter weight than metallic bearings

Swapping composite plastic bushings for metallic bushings can cut wall thickness by 25% or more. That’s because metal bushings need additional thickness to compensate for their more rapid rate of wear. Add to that the difference in density between standard polymer materials and metals—1 to 3 g/cm3 vs. 7 to 9 g/cm3—and the weight reduction available with plastic bearings is obvious.

2. Corrosion-resistant

Metal-free iglide® plastic bushings don’t rust, and most grades don’t deteriorate in dilute acidic and basic solutions or in traditional lubricants. The iglide® product line also includes bushings that can resist hydrochloric acid and other concentrated acids, as well as high- energy and UV radiation. Chemical resistance can change with temperature and chemical concentration, so be sure to take your specific application conditions into account.

Plastic instead of metal: longer service life & 40% cost saving

3. No External lubricant necessary

iglide® plastic bushings are designed to run dry without adding external lubrication. Fiber reinforcements create millions of tiny chambers, which house microscopic solid lubricant particles that are released as the shaft starts to move. Homogeneous construction means lubricant can’t be pressed out, eliminating the need for periodic relubrication.

4. More vibration dampening. Forgiving of shock and edge loads

Plastic bearings run quietly and absorb or dampen mechanical vibrations. Their mechanical loss factor, an indicator of vibration-damping capability, is up to 250 times that of metallic bearings. Fiber reinforcement tailored to application requirements helps the bearings withstand shock and edge loads.